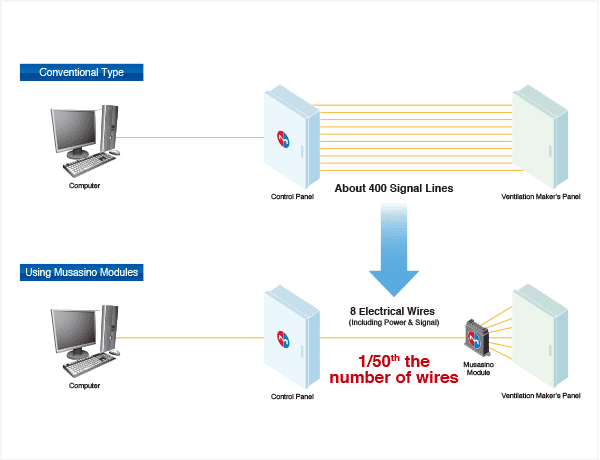

STEP.1 Cable-Saving

In-house production of core modules such as alarm devices, measuring instruments, and control equipment, etc., allows for a reduction in cabling. Reducing the number of cables has various knock on effects, such as increased loading space and reduced weight.

Case study of a PCTC’s control equipment and ventilation

Cables reduced from 400 to 8!

The core module was produced in-house, and then installed in the ventilation maker’s panel. By controlling the ventilation through our panel and module, we were able to reduce the number of cables required from 400 to just eight. This was a huge reduction in wiring.

This reduction of wiring increased the area available for cargo and reduced costs.

The weight of the ship is also lighter as a result. Reducing the amount of space needed for the cables brought a number of benefits, including increased cargo space, improved fuel efficiency with a lighter hull, and reduced costs for procurement and electrical work.

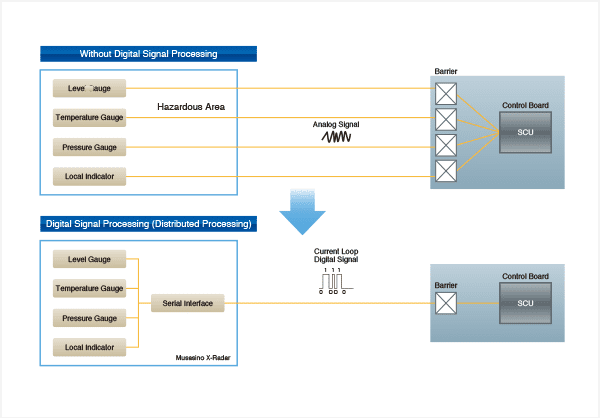

Unification of Signals in Hazardous Area & Reduced Cabling

Stand-alone explosion-proof equipment for digitized wiring.

Traditionally, cargo tank level gauges, temperature gauges, pressure gauges, and local indicators in hazardous areas sent separate analog signals to the control panels. Musasino’s radar type level gauge LEX, however, processes and digitizes signals from each measuring instrument in the hazardous area, and unifies the signals for transmission to the control panel. It functions as a stand-alone explosion-proof device. As a result, the wiring required from each device can be reduced, and an overall reduction in cabling can be achieved even in hazardous areas.

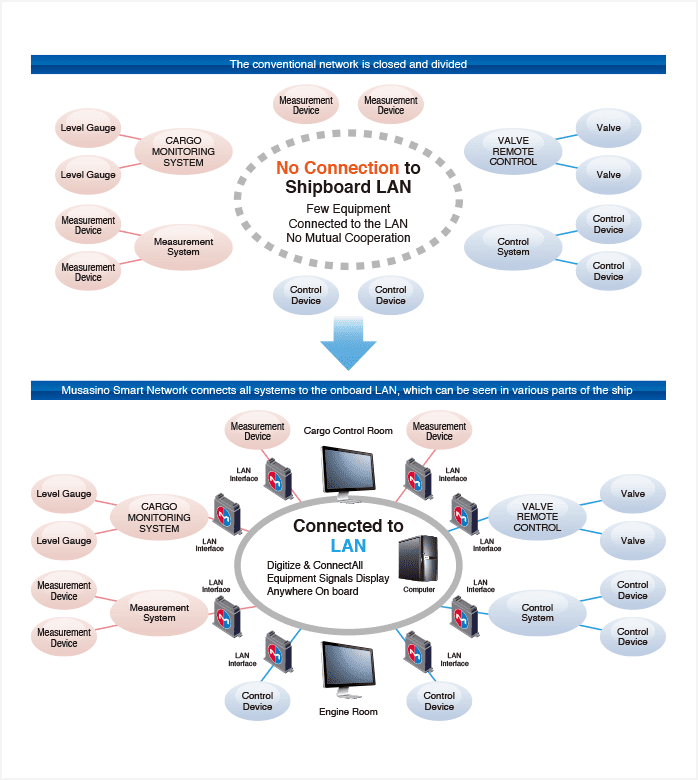

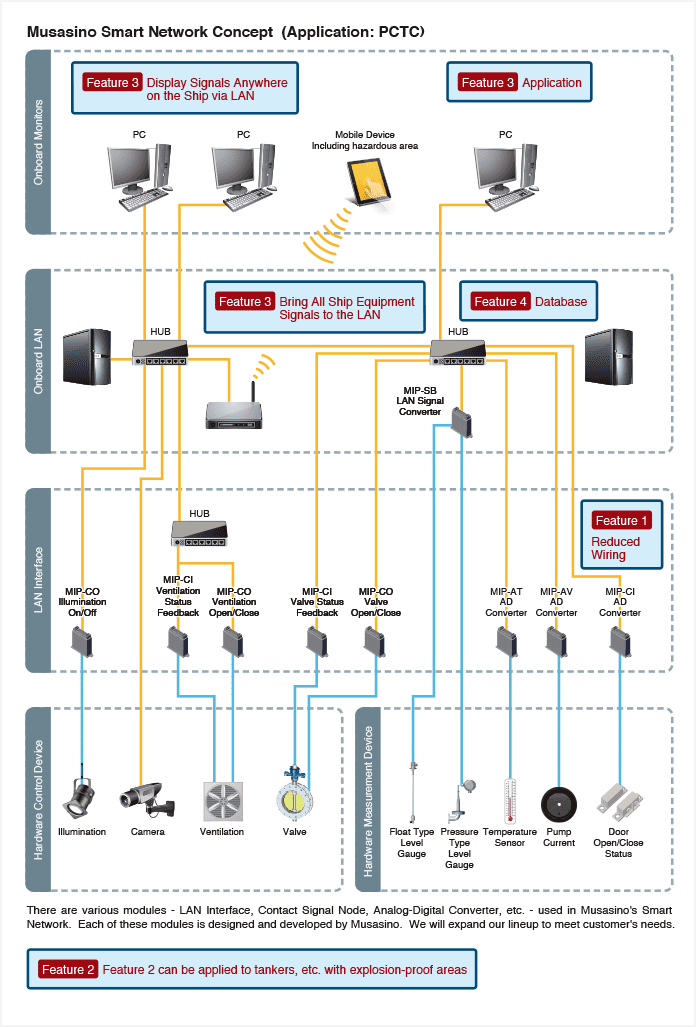

STEP.2 Shipboard LAN

There are already a lot of commercial ships with onboard LAN’s, but there are not a lot of ships that have intercommunication between ship equipment. This is no different from having individual closed networks before shipboard LAN’s were introduced. Musasino builds open networks according to a customer’s requirements, bringing in equipment signals mainly from the engine room and cargo control room to be displayed at various locations on the ship via LAN.

Musasino’s LAN interface and digitize analog signals from various equipment onboard.

The system digitizes signals that need computerto be connected to the LAN, and then consolidates the information on the LAN.

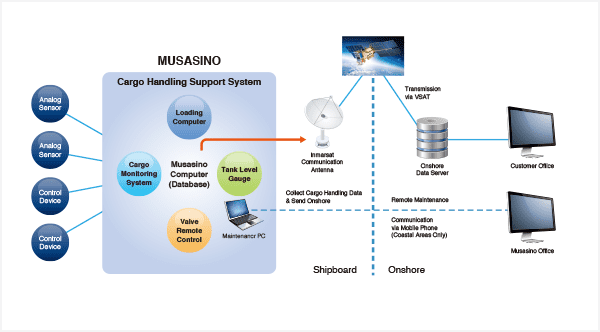

STEP.3 Database Creation

Musasino’s systems include a computer with a built-in database function as standard. As a result, data from equipment connected to the Musasino system is accumulated in the database, and required data can be uploaded on and off the ship via the shipboard LAN, telephone, or satellite connections.

STEP.4 Tailored Solutions

Musasino proposes solutions tailored to our customers' needs, taking advantage of the benefits in the previous steps and our extensive experience in the marine equipment industry. For example, information from measurement instruments can be displayed, and equipment controlled, from a crew member's cabin on a smart phone or tablet, with the data stored in a database on the ship or downloaded to an onshore office. By incorporating signals from all of the equipment onboard, unique applications combining marine equipment can be created.

| Challenge | Solution | Overview |

|---|---|---|

| Improve Maintenance Efficiency | Comprehensive Equipment Management | Device information is imported to the LAN via our interface, and then can be transmitted to operators onshore. |

| Cargo Handling / Equipment Status History Management | Shipboard cargo handling equipment information, such as liquid level, is stored in a database, and historical information can browsed onshore. | |

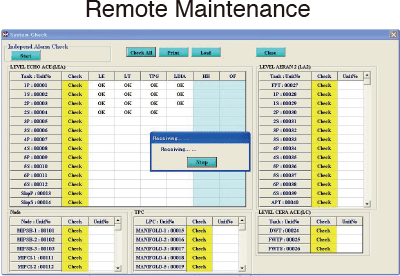

| Remote Maintenance | Remotely monitor equipment conditions from shore, and determine maintenance approaches when an issue arises. | |

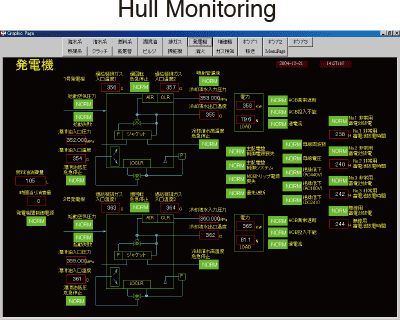

| Monitor for Hull Abnormalities | Monitor conditions of rotating equipment(like motors) with a vibration sensor, and detect hull abnormalities in advance. | |

| Safe Operation | Alarm Monitoring | View the time a tank alarm occurs and analyze the cause of the accident. |

| Pipeline Condition Confirmation | Retrieve information on valve position and pipeline temperatures to check the state of the pipeline. Prevent contamination accidents. | |

| Camera Monitoring | Images from external cameras can be used to for safety surveillance and to surveil suspicious individuals. |

| Solution | Overview |

|---|---|

| Improve Maintenance Efficiency | |

| Comprehensive Equipment Management | Device information is imported to the LAN via our interface, and then can be transmitted to operators onshore. |

| Cargo Handling / Equipment Status History Management | Shipboard cargo handling equipment information, such as liquid level, is stored in a database, and historical information can browsed onshore. |

| Remote Maintenance | Remotely monitor equipment conditions from shore, and determine maintenance approaches when an issue arises. |

| Monitor for Hull Abnormalities | Monitor conditions of rotating equipment(like motors) with a vibration sensor, and detect hull abnormalities in advance. |

| Safe Operation | |

| Alarm Monitoring | View the time a tank alarm occurs and analyze the cause of the accident. |

| Pipeline Condition Confirmation | Retrieve information on valve position and pipeline temperatures to check the state of the pipeline. Prevent contamination accidents. |

| Camera Monitoring | Images from external cameras can be used to for safety surveillance and to surveil suspicious individuals. |

Musasino Smart Network Concept(Application: PCTC)

There are various modules - LAN Interface, Contact Signal Node, Analog-Digital Converter, etc. - used in Musasino’s Smart Network. Each of these modules is designed and developed by Musasino.

We will expand our lineup to meet customer’s needs.