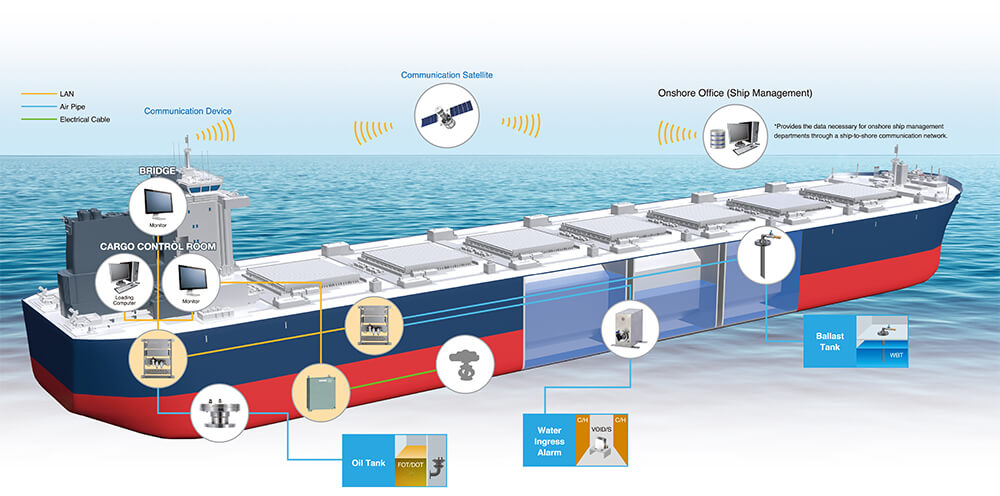

System Configuration

Concept Movie

Three patented technologies achieve the dream of very high accuracy

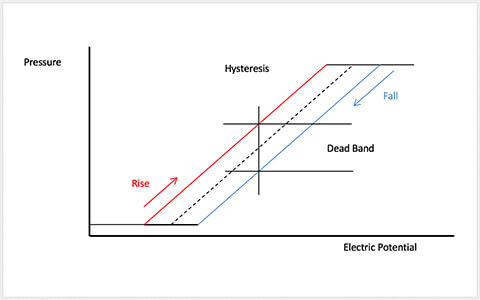

Digital × AI technology solves the hysteresis problem

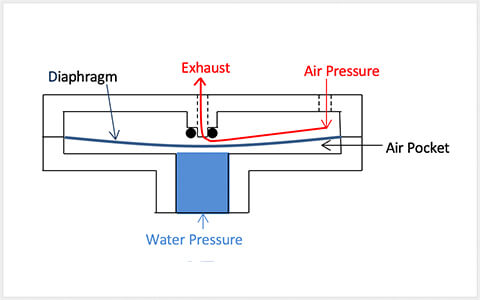

In measuring liquid levels in which a change in pressure is received at a diaphragm and electrically converted by a strain gauge, hysteresis (historical phenomenon) occurs in the detected electrical potential as the pressure rises or falls. Large margins of error in measurements lead to poor accuracy.

LAX solves the hysteresis problem by combining zero point correction of the pressure sensor in the L-Core, digital processing, and AI technologies. This enables a very high accuracy of ±10 mm.

In addition, an air pocket is created between the receiving surface of the diaphragm and the liquid, thus eliminating problems with electrolytic corrosion or calcium buildup.

Using three (including pending) of Musasino’s patented technologies, advanced digital processing and AI technology, provide performance that could not be achieved with analog.

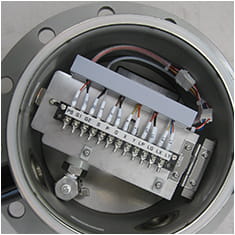

LAX-WAC Diaphragm type

measurement without bubbles

Innovative Pulse Purge Type volume Gauge with Exceptional Measurement Accuracy

±25mm corresponding to Level Master

Musasino’s patented pulse purge method L-CORE takes high accuracy measurements. Temporarily discharging a higher pressure of compressed air, and stopping the air flow during measurement, eliminates the pressure loss and fluctuation, allowing for high accuracy measurements. This method suppresses hysteresis, and results in high-precision liquid level measurements.

| Accuracy | |

|---|---|

| LA-PH/LA-WAC | ±25mm |

Measurement accuracy test

Shirakawa factory LAX Measurement data

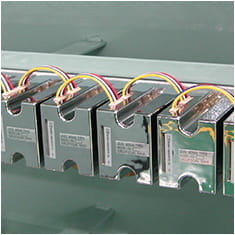

Module (MIU) Developed in-house.

Easily Acquire a Wide Variety of Signals.

MIU is a proprietary interface, developed to capture all of a ship’s data. The unit consists of a series of nodes that enable acquisition of various types for signals – analog, serial, contact, LAN, etc. By combining various nodes corresponding to the types of data required, managing cargo handling-related equipment such as monitoring and control systems – including third party systems – can be integrated.

Automatic Atmospheric Pressure Correction (patented) & Temperature Compensation.

Self-correcting for high accuracy measurements.

Another feature that results in high accuracy measurements is the self-correction function. An atmospheric pressure reading is taken regularly, and in the pulse purge method a zero point correction is made when the airflow is stopped. As a result, there is no restriction on where the unit can be installed, and errors due to aging of the pressure detector are prevented, so that stable, high accuracy measurements can be made over the long term. Because temperature may also affect the pressure sensors measuring liquid level, temperature compensation is also done.

General Specifications

| Measurement Method | Pulse Purge type |

|---|---|

| Power Supply | AC100〜220A |

| Accuracy | ±25mm / LAX-PH・ LAX-WAC |

| Protection Class | MPP-Unit: IP44 Alarm Panel: IP22 |

| Air quality | Dry air for measurement |

| Ambient Temp. Range | 5-55℃ (MPP Unit / Alarm Panel) |

| Interface | LAN, RS485 |

| Classification Approval | ABS, BV, CCS, DNV, KR, LR, NK |

Detector sensor

Various Detectors to Match the Applications.

TOP-MOUNT type purge head installed on the top of the tank, WAC purge head that does not discharge air to the tank for drinking / fresh water tanks and E/R storage tanks in the E/R, and the immersion alarm device ADM that can measure two points with one unit, are available according to the application.

LAX-PH

Simple structure & maintenance-free

Accuracy: ±25mm

Applicable Tanks: Ballast Tanks, FO/DO Tanks, Draft Gauges

LAX-ADM Water Ingress Alarm

Fail safe function, liquid level measurement even after an alarm

Accuracy: ±30mm / ±10mm

Application: Ingress Alarm, Bilge Alarm

LAX-WAC

Diaphragm type, measurement without bubbles

Accuracy: ±25mm

Applicable Tanks: Drinking Water, Fresh Water, Settling Tanks, Storage Tanks, Service Tanks, Other Engine Room Tanks